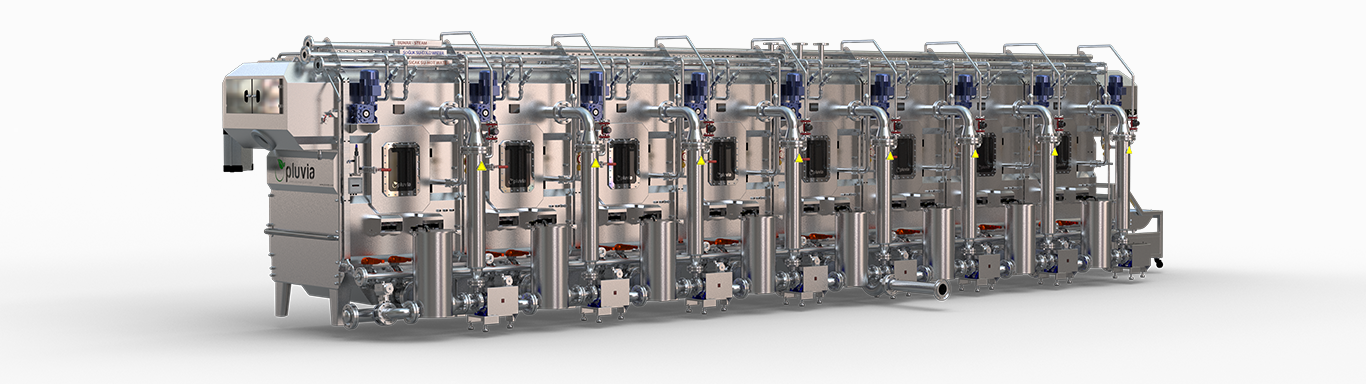

HIGH EFFICIENCY

HIGH EFFICIENCY

HIGH PRODUCTIVITY

HIGH PRODUCTIVITY

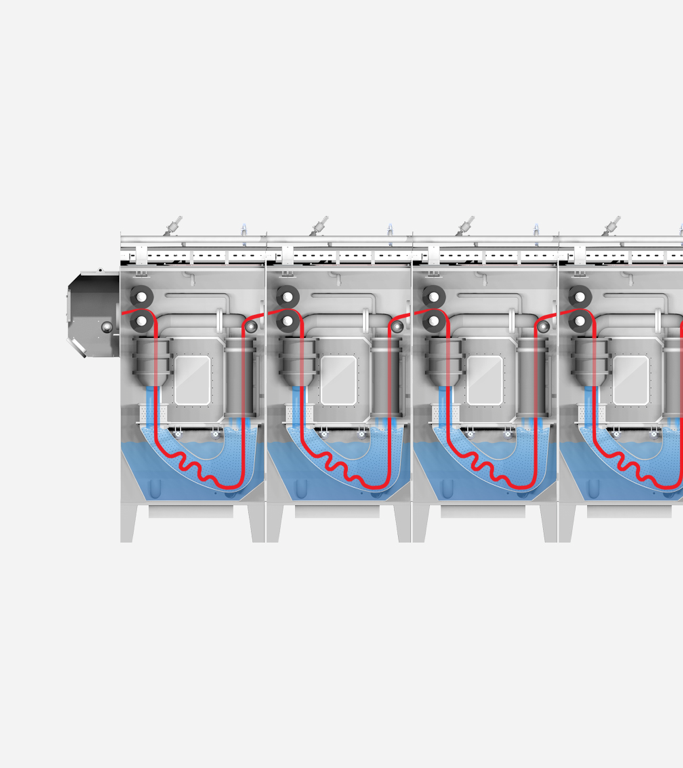

HIGH QUALITY

HIGH QUALITY

%30-50

CAPACITY INCREASE

%50–80 WATER SAVING

%50–80 STEAM SAVING

%30–50 ELECTRICITY SAVING

LESS PEELING

HIGHER FASTNESS

LESS ENERGY

LESS ENERGY

HIGH productivity

HIGH productivity

HIGH Quality

HIGH Quality