HIGH EFFICIENCY

HIGH EFFICIENCY

HIGH PRODUCTIVITY

HIGH PRODUCTIVITY

HIGH QUALITY

HIGH QUALITY

HIGHER AFFINITY

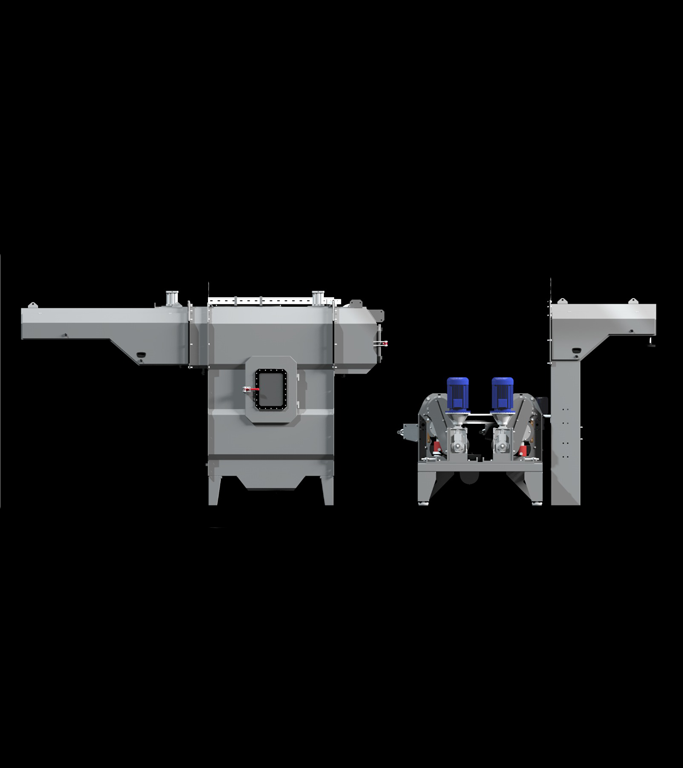

OPEN WIDTH PAD STEAM OPTICAL APPLICATION

OPEN WIDTH PAD STEAM OPTICAL APPLICATION

LESS ENERGY

LESS ENERGY

HIGH productivity

HIGH productivity

HIGH Quality

HIGH Quality